Reinventing Workforce Training: The Role of Industrial Simulations

Providing an edge in today's competitive industrial arena calls for innovative approaches to workforce training. Industrial simulations have emerged as a powerful tool in redefining training and development practices, creating a safer, more efficient and immersive learning environment. This article delves into the rise of industrial simulations, examining its roots, current trends, and its transformative impact on businesses and industries.

The Genesis of Industrial Simulations

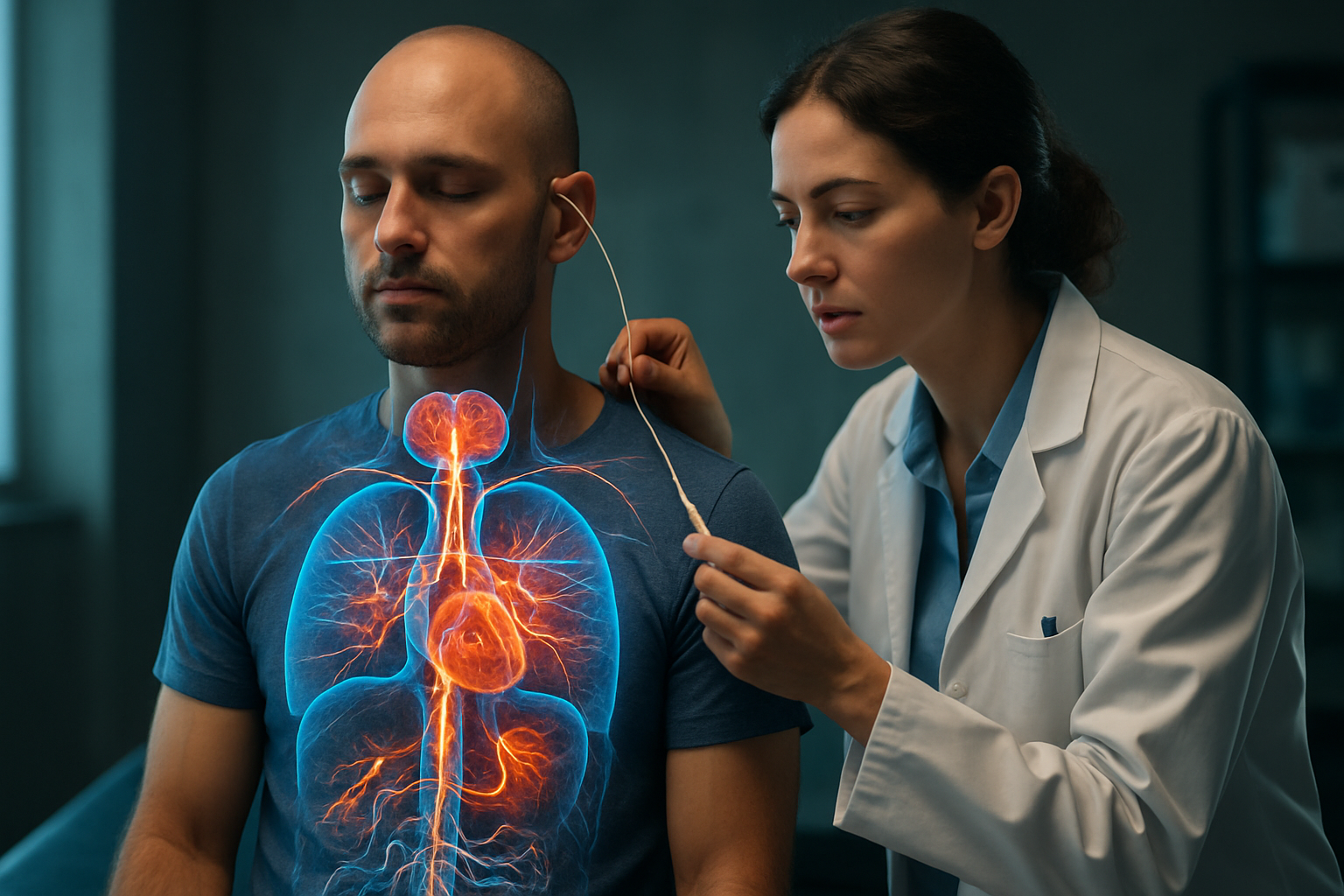

Industrial simulations trace their origins back to the aviation industry, where flight simulators were used to train pilots without the risks and costs associated with real flights. Over the years, technological advancements have refined and expanded the use of simulations, finding applications across diverse industries like oil and gas, healthcare, and manufacturing. As technologies like virtual reality (VR) and augmented reality (AR) mature, the potential of industrial simulations continues to grow.

Current Trends in Industrial Simulations

One of the current trends is the integration of VR and AR with industrial simulations. These technologies offer immersive and interactive experiences, allowing workers to practice and hone their skills in a controlled, risk-free environment. Moreover, advancements in machine learning and artificial intelligence are enhancing the realism and adaptability of simulations, providing a more personalized training experience.

Impact, Benefits, and Challenges of Industrial Simulations

Industrial simulations offer numerous benefits. For one, they allow for risk-free training, which is particularly valuable in high-risk industries. Simulations also enhance learning effectiveness, as they offer hands-on experience and immediate feedback. Moreover, they can save costs by reducing the need for physical training materials and facilities.

However, implementing industrial simulations is not without challenges. High initial investment, technological complexities, and the need for specialized skills can be potential barriers. Despite these obstacles, the advantages they offer make them a worthwhile investment for businesses striving to boost productivity and enhance workforce skills.

Enhancing Business Practices through Industrial Simulations

-

Leverage simulations for complex task training: Simulations can effectively train employees on complex tasks, reducing the likelihood of errors in real-life operations.

-

Use simulations for safety training: High-risk industries can use simulations to train employees on safety protocols without any actual risk.

-

Incorporate feedback mechanisms: Immediate feedback enhances the learning process, helping employees to correct mistakes and improve their performance.

-

Personalize training programs: Use the adaptability of simulations to tailor training programs to individual employee needs.

Industrial simulations, backed by advancements in technology, are revolutionizing workforce training, offering safer, more effective, and cost-efficient solutions. Despite the challenges, their potential to transform industrial operations and enhance productivity is immense. As businesses seek to gain a competitive edge, embracing industrial simulations could be a game-changing move.